|

VIEWS:

462921

|

TEFLON,SILICONE, CONTROL, EQUIPMENT, MEDICAL WIRE & CABLE

(1) SILICONE RUBBER SERIES |

TEFLON, SILICONE, CONTROL, EQUIPMENT, MEDICAL WIRE & CABLE

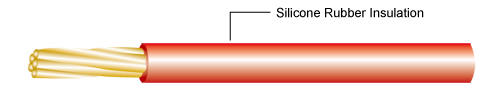

(A) UL3135/3125 STLICONE RUBBER SINGLE CORD

RATING : 200℃, 600 VOLTS / 150℃, 600 VOLTS

|

CONDUCTOR |

INSULATION

THICKNESS |

OVERALL

DIAMETER |

CONDUCTOR

RESISTANCE

AT 200℃ |

|

AWG |

NO./MM |

MM |

MM |

OHM/KFT |

|

26 |

7/0.160 |

0.77 |

2.0±0.1 |

45.20 |

|

24 |

11/0.160 |

0.77 |

2.2±0.1 |

29.30 |

|

22 |

17/0.160 |

0.77 |

2.4±0.1 |

16.70 |

|

20 |

21/0.180 |

0.77 |

2.5±0.1 |

10.50 |

|

18 |

34/0.180 |

0.77 |

2.8±0.1 |

6.64

|

|

16 |

26/0.254 |

0.77 |

3.1±0.1 |

4.18 |

|

14 |

41/0.254 |

0.77 |

3.5±0.1 |

2.62 |

|

12 |

65/0.254 |

0.77 |

3.9±0.1 |

1.65 |

|

10 |

105/0.254 |

0.77 |

5.1±0.1 |

1.04 |

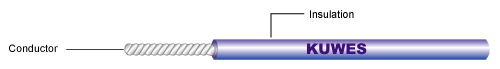

(B) UL3239 HIGH-VOLTAGE WIRE

(NOMINAL VOLTAGE) : 3KV, 6KV, 10KVDC

(TEMPERATURE) : - 60℃~150℃

USE :INSIDE WIRING FOR A VARICTY OF HOUSEHOLD APPLIANCES, MICRO-WAVE OVEN, NEON LAMPS, FASCIMILE, DUPLICATOR PRINTER, LCD ETC.

|

CONDUCTOR |

INSULATOR |

ELECTRICAL

CHARACTERISTIC

|

|

AWG |

COMPOS.NO

MM |

DIAMRTER

MM |

DIAMETER MM |

OVER DIAM MM |

REALST.MAX CUC

.C20℃

0HM/KM

|

INTENS.MAXL

MAX A 170℃

-AMR

|

|

3KV |

6KV |

10KV |

3KV |

6KV |

10KV |

|

24 |

7/0.20 |

0.59 |

0.6 |

0.8 |

0.95 |

1.79 |

2.19 |

2.5 |

52.5 |

2.0 |

|

22 |

22/0.14 |

0.72 |

0.6 |

0.8 |

0.95 |

1.92 |

2.32 |

2.7 |

40.10 |

3.60 |

|

20 |

19/0.20 |

0.93 |

0.6 |

0.8 |

0.95 |

2.13 |

2.53 |

2.85 |

20.00 |

7.10 |

|

18 |

19/0.254 |

1.14 |

0.6 |

0.8 |

0.95 |

2.34 |

2.74 |

3.25 |

13.70 |

10.00 |

|

16 |

19/0.287 |

1.47 |

0.6 |

0.8 |

0.95 |

2.67 |

3.07 |

3.55 |

7.90 |

14.30 |

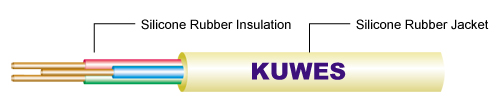

(C) UL4330 SILICONE RUBBER INSULATED AND JACKET CABLE

(RATING : 150℃, 300VOLTS)

| CONDUCTOR |

NO. OF

CORE

|

INSULATION

THICKNESS

|

INSULATION

THICKNESS

|

OVERALL

DIAMETER

|

|

AWG |

NO./MM |

MM |

MM |

MM |

|

24 |

7/0.20 |

2 |

0.4 |

0.7 |

4.0 ± 0.15 |

|

3 |

5.0 ± 0.15 |

|

22 |

22/0.14 |

2 |

0.4 |

0.7 |

4.2 ± 0.15 |

|

3 |

5.2 ± 0.15 |

|

20 |

19/0.20 |

2 |

0.5 |

0.7 |

5.0 ± 0.15 |

|

3 |

6.0 ± 0.20 |

|

18 |

34/0.18 |

2 |

0.6 |

0.7 |

5.8 ± 0.20 |

|

3 |

6.8 ± 0.20 |

|

16 |

30/0.254 |

2 |

0.7 |

0.8 |

7.5 ± 0.20 |

|

3 |

8.5 ± 0.25 |

|

14 |

40/0.254 |

2 |

0.7 |

0.8 |

8.5 ± 0.20 |

|

3 |

9.5 ± 0.25 |

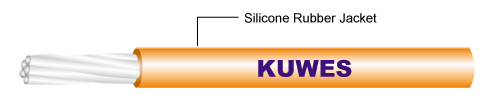

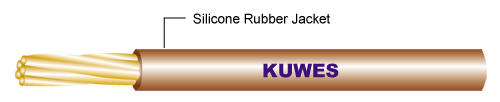

(D) UL3132 SILICONE RUBBER WIRE

USE :

INTERNAL WIRING OF APPLIANCES WHERE TOTALLY ENCLOSED.RATING 150℃ 300V

CONSTRUCTION :

|

CONDUCTOR |

INSULATOR

THICKNESS

|

STANDARD FINAL

OUTER DIAMETER

|

TESTING

VOLTAGE

|

INSULATION

RESISTANCE

|

|

DIAMETER OR

STANDARD

CROSS-SEC AREA

|

CONDUCTION |

DIAM |

|

NO./MM |

MM |

MM |

MM |

V/MIN |

M£[-KM |

|

0.5MM

0.8

1.0

1.2

1.6

|

|

0.5

0.8

1.0

1.2

1.6

|

0.4

0.4

0.5

0.5

0.6

|

1.3

1.6

2.0

2.2

2.8

|

1500

1500

1500

1500

1500

|

300

300

300

300

200

|

|

0.3 MM2

0.5

0.75

1.25

2.0

3.5

5.5

|

12/0.18

20/0.18

30/0.18

50/0.18

37/0.26

45/0.32

35/0.45

|

0.7

1.0

1.2

1.5

1.8

2.5

3.1

|

0.4

0.5

0.5

0.6

0.8

0.8

0.8

|

1.5

2.0

2.2

2.7

3.4

4.1

4.7

|

1500

1500

1500

1500

1500

1500

1500

|

300

300

300

200

200

200

200

|

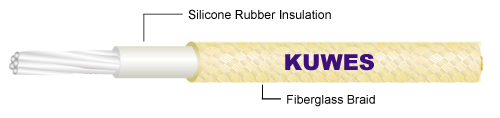

(E) UL3122 SILICONE RUBBER GLASS

BRAIDED WIRE

USE :

INTERNAL WIRING OF APPLIANCES.

RATING 200℃ 300V

CONSTRUCTION :

|

CONDUCTOR |

INSULATOR

THICKNESS |

WEAVING

THICKNESS

|

STANDARD FINAL

OUTER DIAMETER |

TESTING

VOLTAGE

|

|

DIAMETER OR

STANDARD

CROSS-SEC AREA

|

CONDUCTION |

DIAM |

|

NO./MM |

MM |

MM |

MM |

MM |

M£[-KM |

|

0.5MM

0.6

0.8

1.0

1.2

1.6

2.0

|

|

0.5

0.6

0.8

1.0

1.2

0.6

2.0

|

0.4

0.4

0.4

0.4

0.4

0.5

0.6

|

0.2

0.2

0.2

0.2

0.2

0.2

0.2

|

1.7

1.8

2.0

2.2

2.4

3.0

3.6

|

1500

1500

1500

1500

1500

1500

1500 |

|

0.3 MM2

0.5

0.75

1.25

2.0

3.5

5.5

8

|

12/0.18

20/0.18

30/0.18

50/0.18

37/0.26

45/0.32

35/0.45

50/0.45

|

0.7

1.0

1.2

1.5

1.8

2.5

3.1

3.7

|

0.4

0.4

0.4

0.4

0.5

0.6

0.6

0.8

|

0.2

0.2

0.2

0.2

0.2

0.25

0.25

0.25

|

1.9

2.2

2.4

2.7

3.2

4.2

4.8

5.8

|

1500

1500

1500

1500

1500

1500

1500

1500 |

(F) UL3243 SILICONE RUBBER THIN COPPER WIRE (RSF WIRE)

USE :

SUITABLE FOR RELAY, MOBILE LINES, AND LEADING LINE FOR MOBILE JOINTS

RATING 150℃ 300V

CONSTRUCTION :

| CONDUCTOR |

INSULATOR

THICKNESS

|

STANDARD FINAL

OUTER DIAMETER

|

TESTING

VOLTAGE |

INSULATION

RESISTANCE |

|

CONSTRUCTION |

CONDUCTION |

STANDARD

CROSS-SEC AREA

|

|

NO./NO./MM |

MM |

MM2 |

MM |

MM |

V/MIN |

M£[-KM |

|

51/0.05¡@

3/34/0.05¡@

3/51/0.05¡@

7/29/0.05¡@

7/36/0.05¡@

7/55/0.05¡@

7/66/0.05¡@

7/91/0.05¡@

40/0.08¡@

3/20/0.08¡@

3/27/0.08¡@

3/33/0.08¡@

3/50/0.08¡@

7/26/0.08¡@

7/36/0.08¡@

7/57/0.08¡@

7/100/0.08¡@

|

0.5

0.7

0.9

0.9

1.0

1.3

1.4

1.7

0.6

0.9

1.0

1.2

1.4

1.4

1.7

2.1

2.8

|

0.1

0.2

0.3

0.4

0.5

0.75

0.9

1.25

0.2

0.3

0.4

0.5

0.75

0.9

1.25

2.0

3.5

|

0.4

0.4

0.4

0.4

0.5

0.5

0.5

0.6

0.4

0.4

0.4

0.5

0.5

0.5

0.6

0.8

0.8

|

1.3

1.5

1.7

1.7

2.0

2.3

2.4

2.9

1.4

1.7

1.8

2.2

2.4

2.4

2.9

3.7

4.4

|

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

1500V

|

300

300

300

300

300

300

200

200

300

300

300

300

300

200

200

200

200

| |

| | | |

| |

| |

|